Rehabilitation and Development of RTG Cranes at Damietta Container and Goods Trading Company

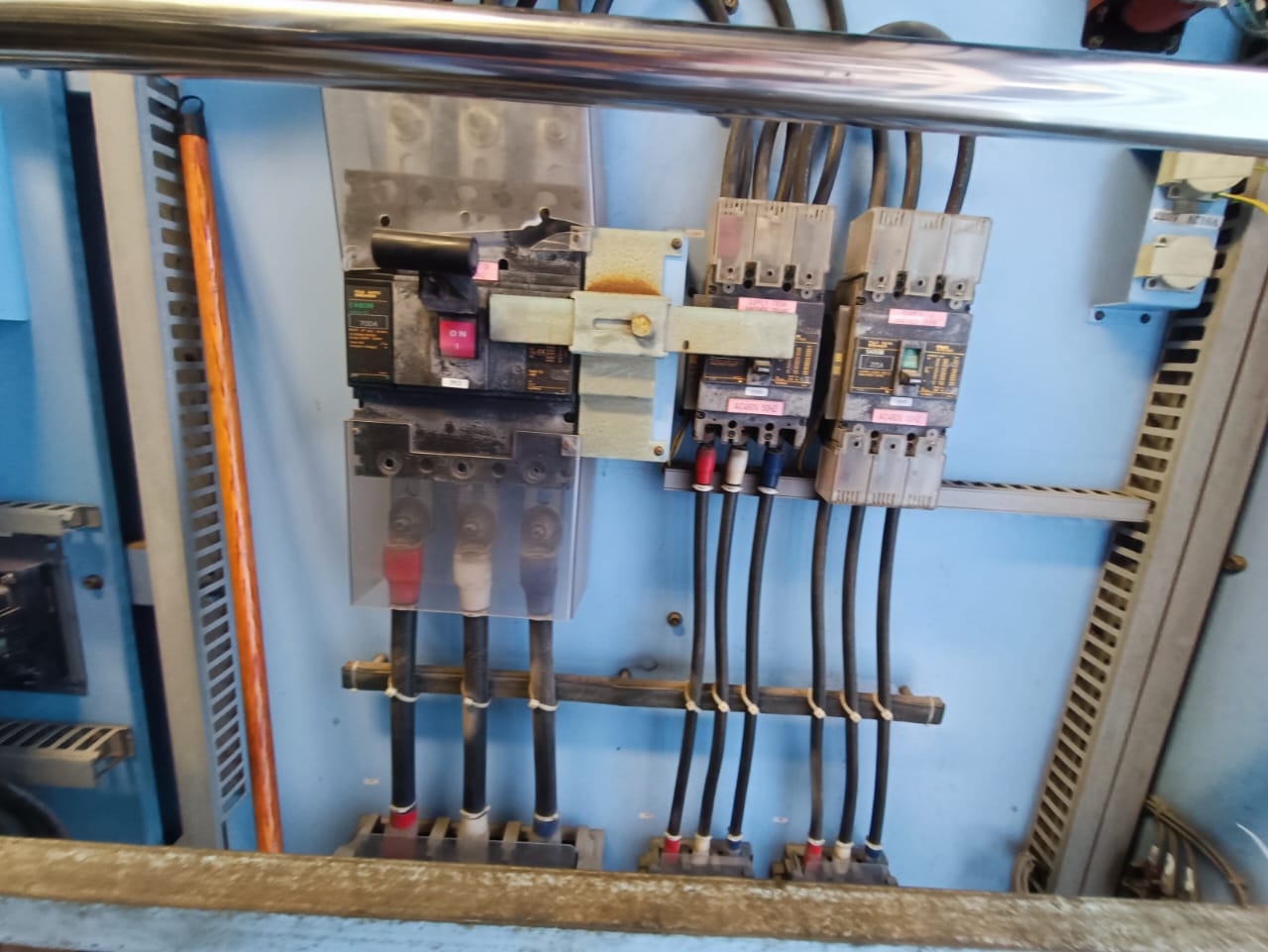

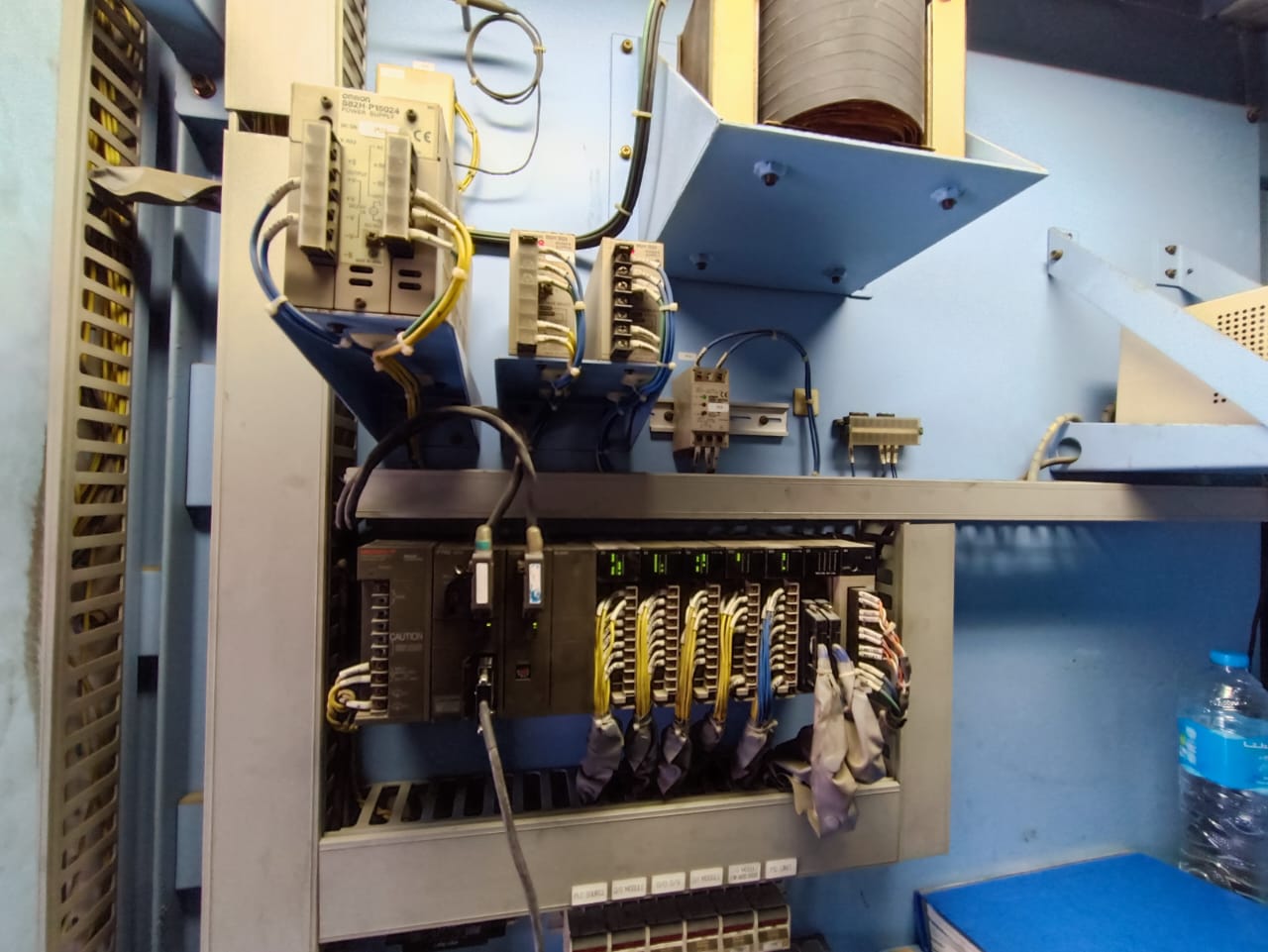

MecTronic Services has successfully rehabilitated and upgraded a number of cranes as part of a project comprising 10 RTG cranes of the Mitsubishi model, manufactured in 2001, with a rated capacity of 40 tons per crane, a height of 18 meters, and a span of 26.5 meters. Upon completion of the rehabilitation, the company conducted the necessary technical tests in accordance with the manufacturer's recommendations and standard values, in the presence of the owner. After passing the tests, the fully rehabilitated cranes were put into service and are operating at full efficiency. MecTronic Services continues to complete the project according to the agreed-upon schedule and plan with the owner.

The qualified work team, equipped with the latest testing and inspection devices, detected and examined the diesel engine and the crane's generator, hydraulic circuits, and fuel circuits, identified the requirements, developed a work plan and timeline, and, after providing the necessary requirements, repaired and modified all mechanical and electrical components in MecTronic Services' workshops and on-site. The crane was handed over to the owner after passing the required tests.

Watch project video

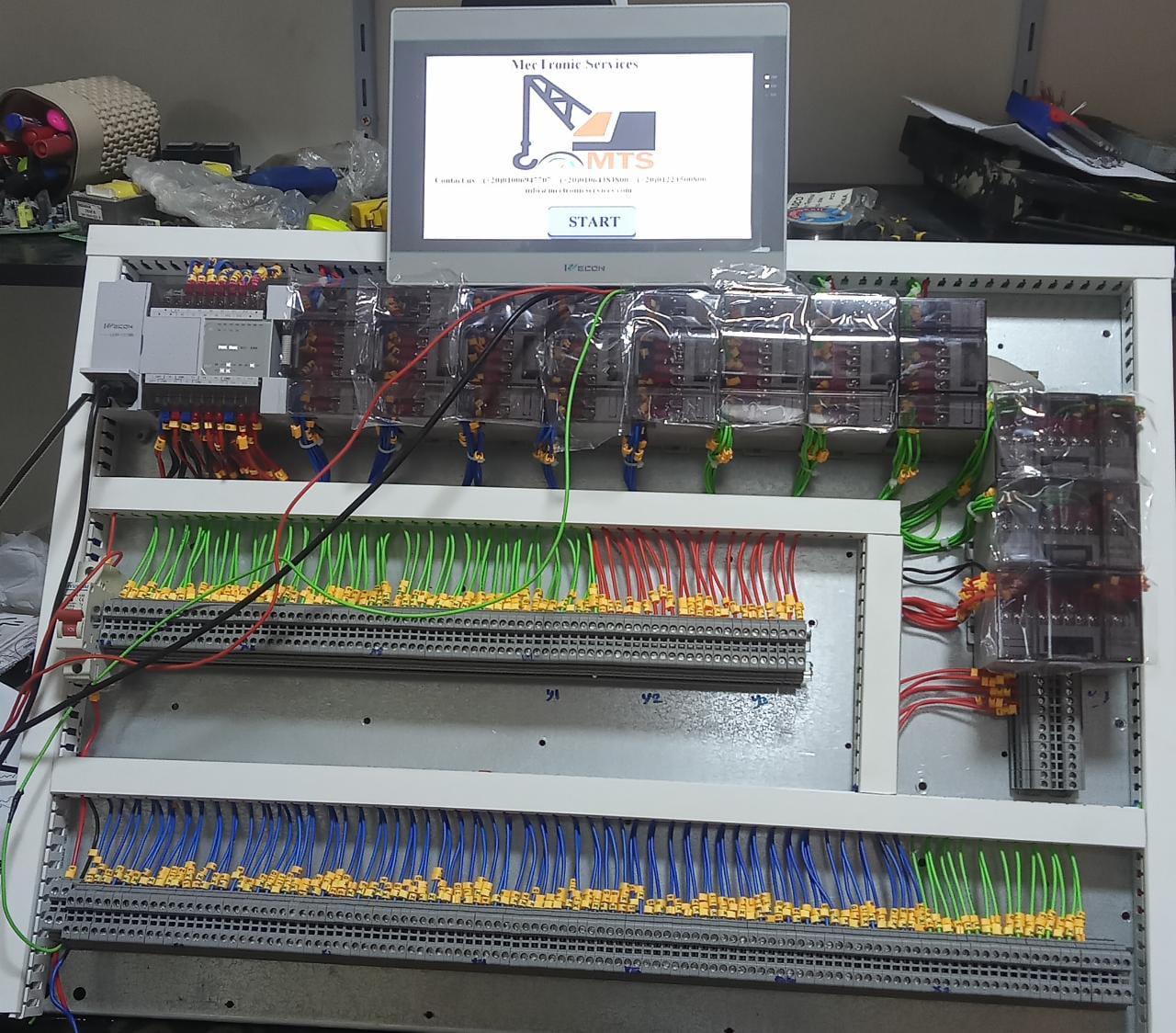

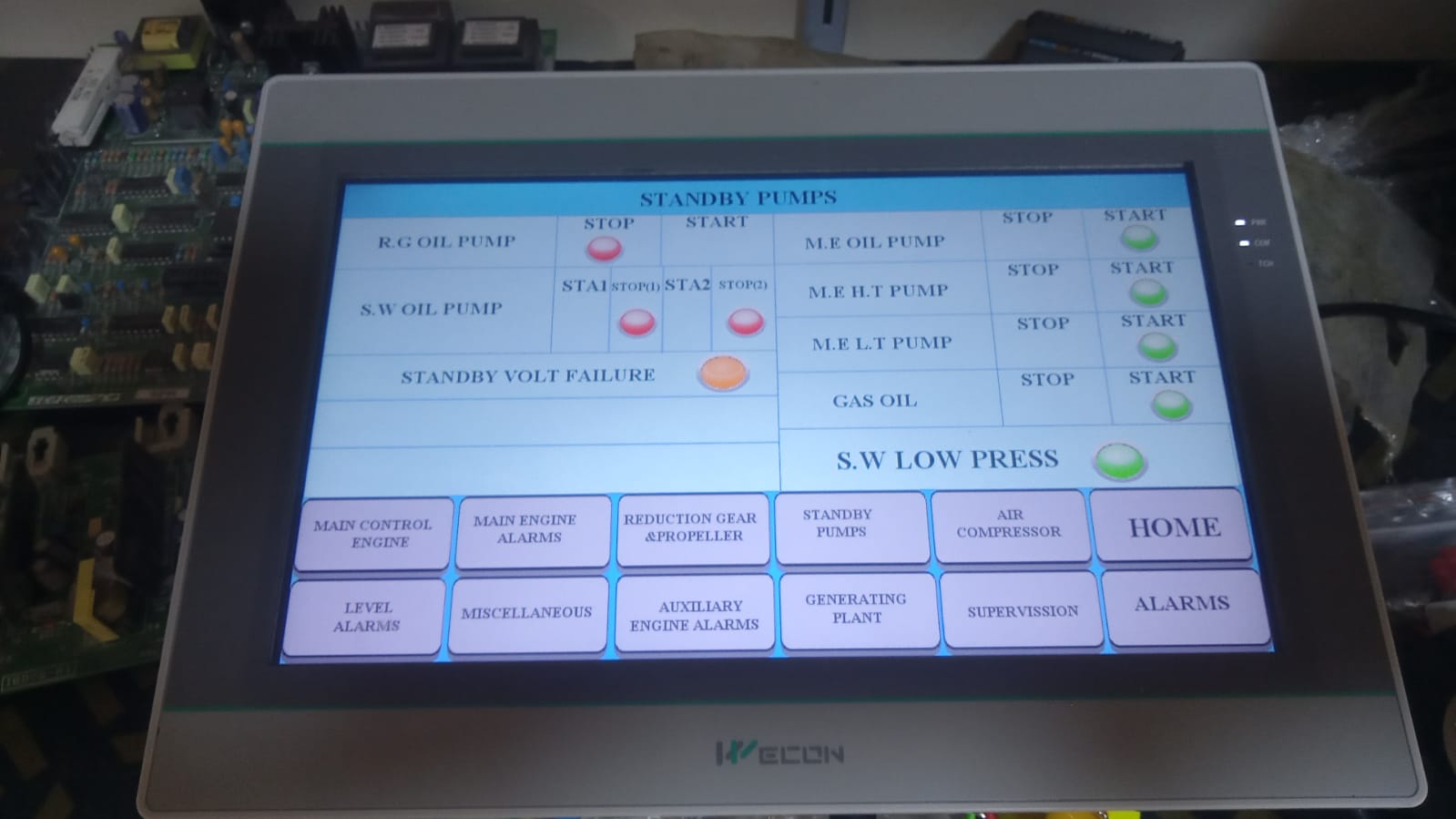

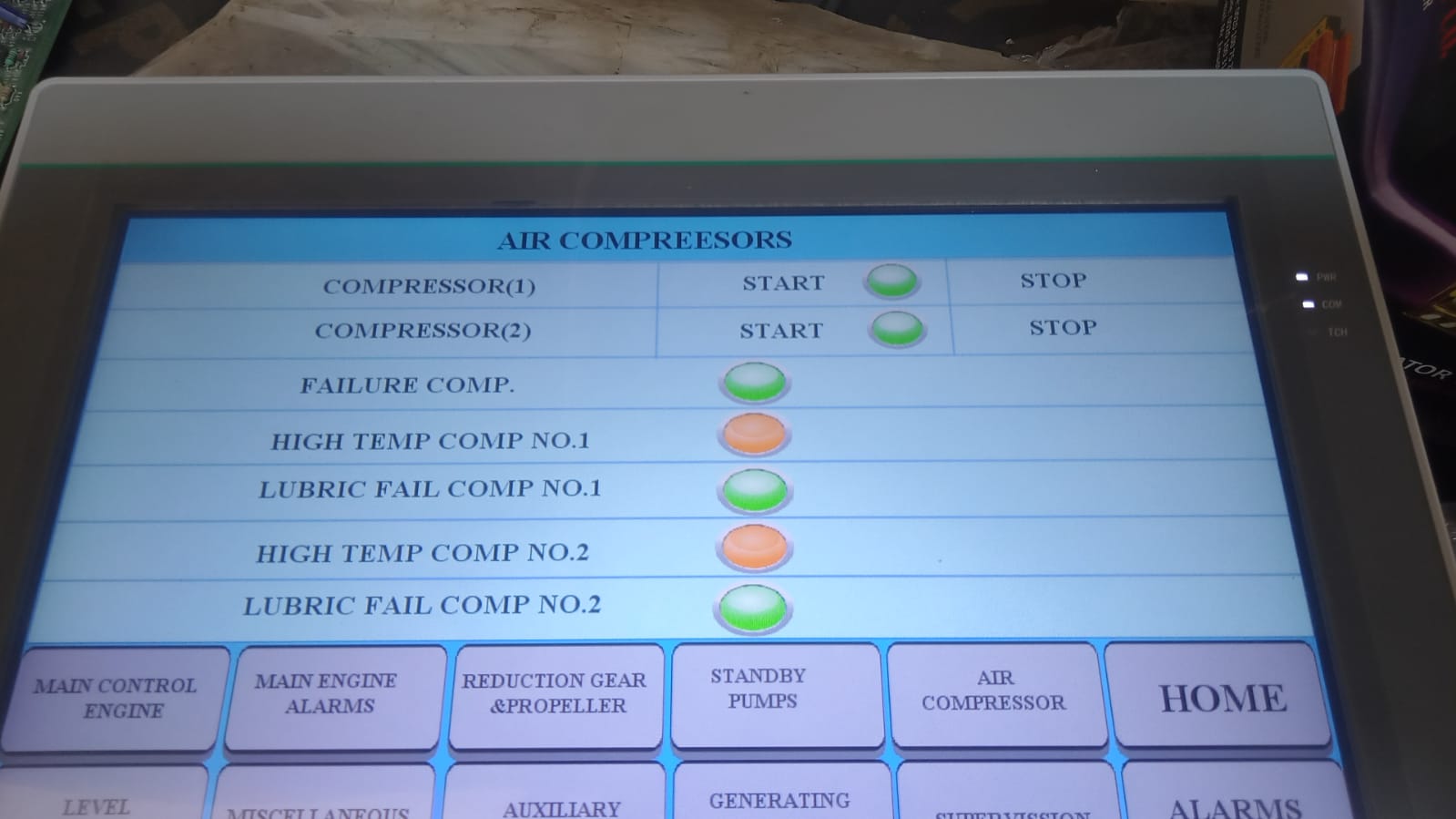

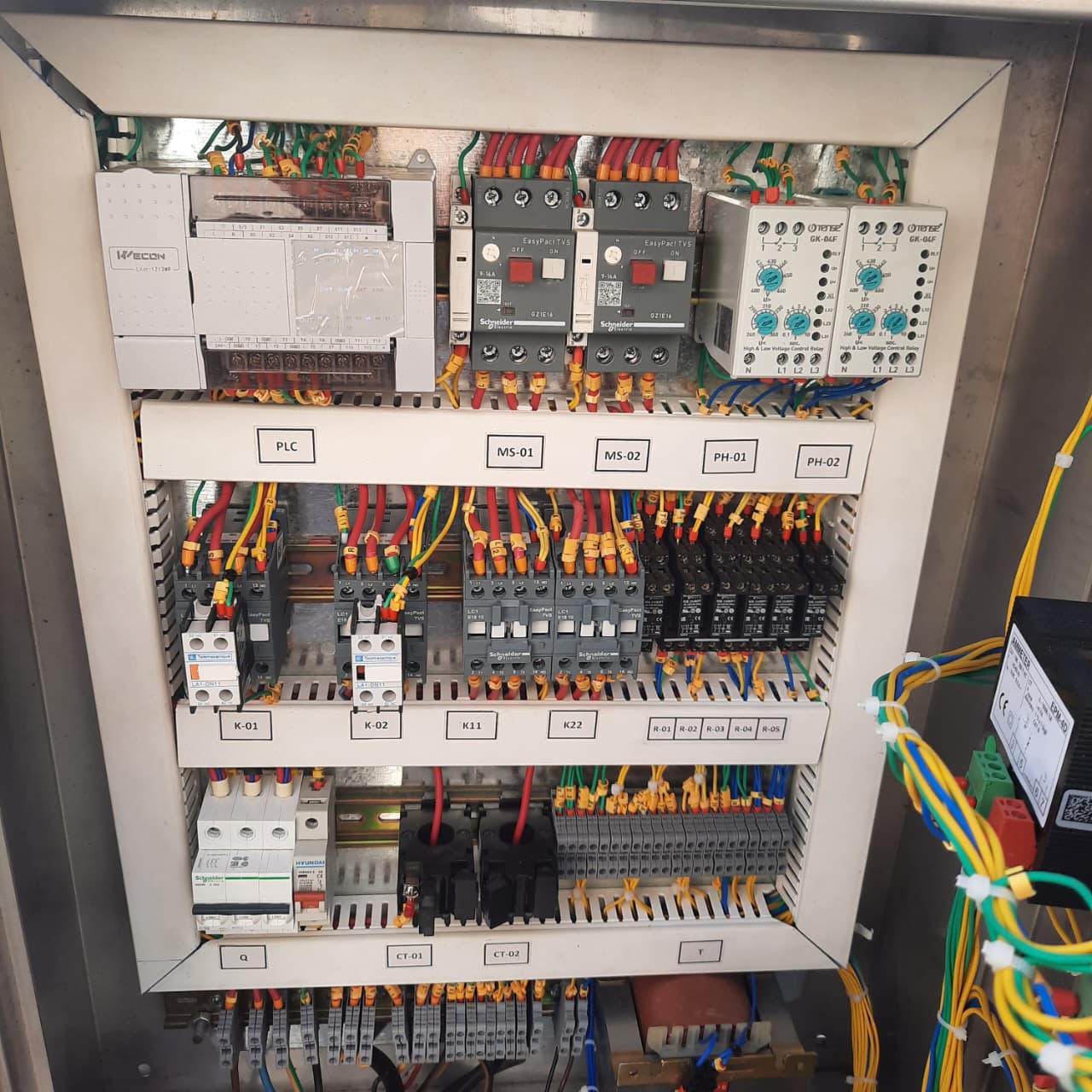

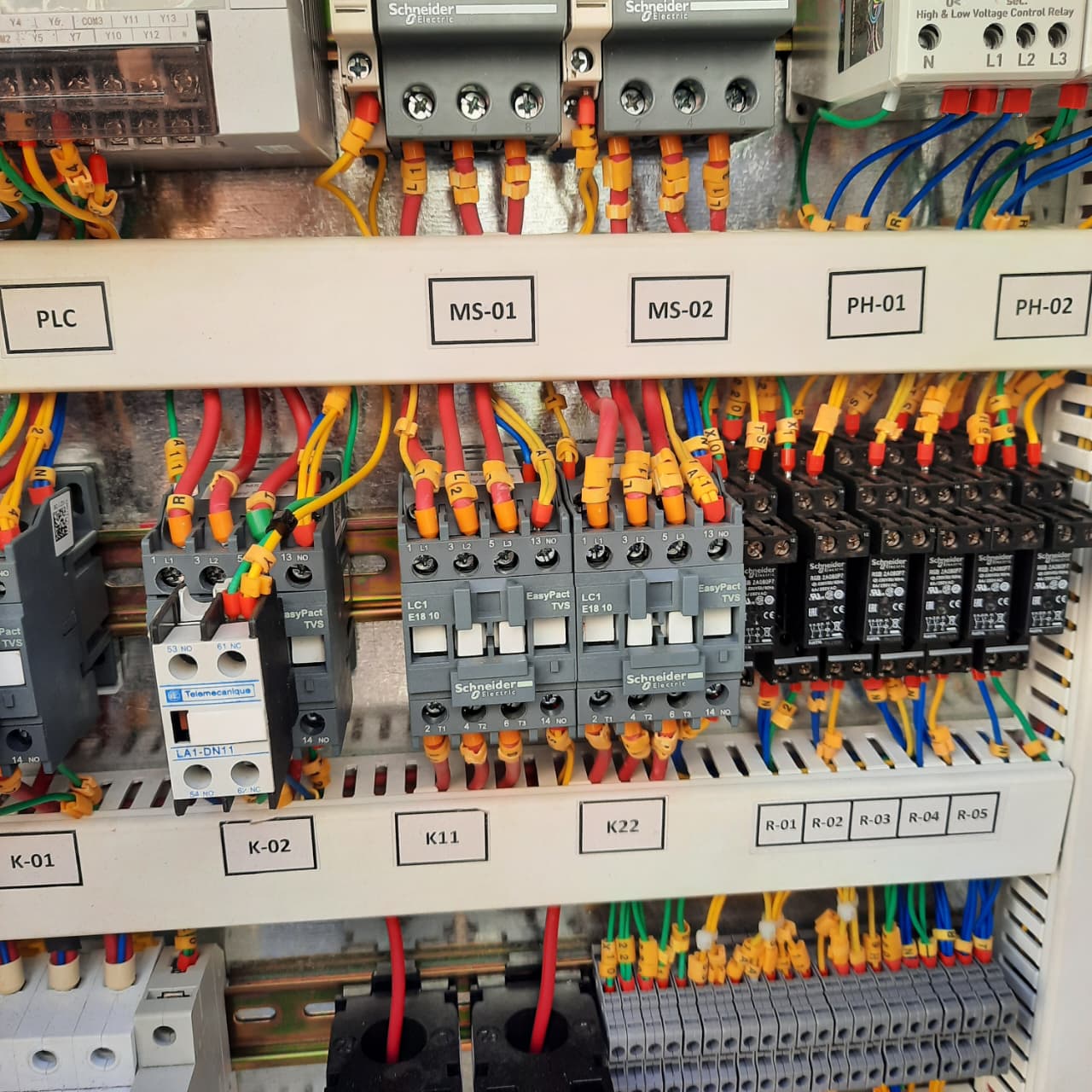

Control System Upgrade for Cargo Ship

MecTronic Services' highly skilled control team has successfully executed a comprehensive upgrade and development of the control system for a cargo ship. This strategic transition from a legacy traditional system to an advanced PLC platform equips operators with precise, real-time monitoring capabilities for alarms and deviations from established standards, ensuring optimal operational integrity.

The upgrade introduces enhanced flexibility and ease of use, enabling proactive

equipment management and preemptive intervention to mitigate potential

failures, thereby upholding the highest levels of operational reliability. This forward

thinking solution aligns with industry best practices to meet both current and future operational demands.

Furthermore, the upgraded control system incorporates a sophisticated feature for

accessing historical alarm data, facilitating detailed event analysis, risk assessment,

and proactive prevention measures. This robust functionality highlights MecTronic

Services' expertise in enhancing maritime efficiency and safety across marine and

ship projects.

Watch project video

Tower Crane Rehabilitation - Model SK448 - AT4

Elevate your operations with MecTronic Services' expert rehabilitation of the SK448-AT4 Tower Crane, where we conduct a thorough inspection of the crane's structure and mechanical components to ensure optimal performance. This is followed by precision disassembly and replacement of worn-out parts to restore durability. Our skilled team then performs advanced repair and maintenance of hydraulic and slewing systems for seamless functionality. The process is complemented by expert sandblasting, painting, and corrosion protection to enhance longevity. We rigorously test and calibrate safety devices and load indicators for maximum reliability. This is followed by precise reassembly and alignment of crane sections to ensure structural integrity. The process concludes with comprehensive load testing and commissioning in compliance with stringent safety standards. Finally, we provide final certification and a professional handover, guaranteeing client satisfaction and safety. Trust MecTronic Services to revitalize your SK448-AT4 with unmatched expertise and quality.

Watch project video

Design, Manufacturing, and Programming of Filling Machine

Unlock precision and efficiency with MecTronic Services' comprehensive solution for the design, manufacturing, and programming of filling machines, where we craft custom designs and fabricate components tailored to your specific needs, followed by seamless assembly and integration of mechanical and electrical systems. Our expert team develops PLC programming and HMI interfaces to enable automated operation with unmatched accuracy, complemented by the strategic installation of sensors, actuators, and control devices. We ensure peak performance through rigorous testing, calibration, and adjustment for precise filling, culminating in final commissioning and comprehensive operator training to empower your team. Trust MecTronic Services to deliver a state-of-the-art filling machine solution with exceptional quality and reliability.

Watch project video

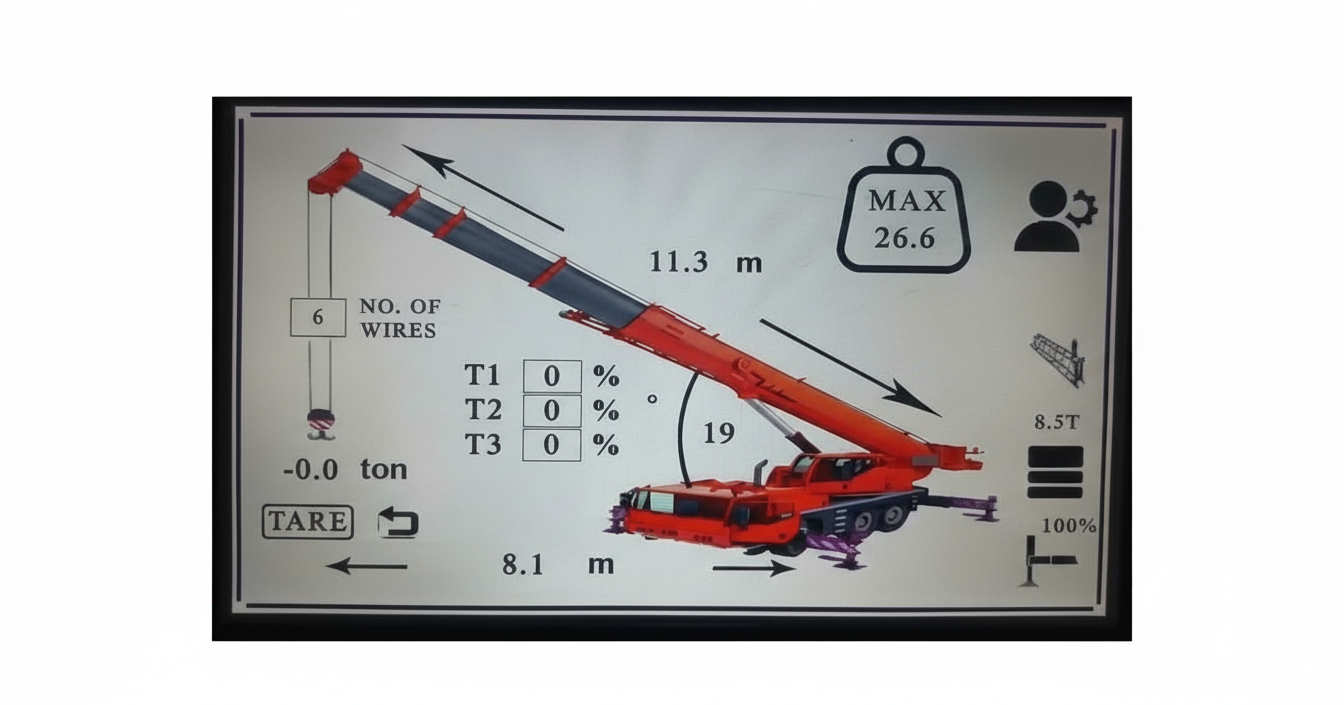

Telescopic Cranes Safety Systems Upgrade

Enhance operational safety with MecTronic Services' expert upgrade of telescopic crane safety systems, where we engineer and install a robust safety framework for load monitoring tailored to your requirements, seamlessly integrating advanced sensors to track load, angle, and boom extension with precision. Our specialists craft sophisticated control logic using PLC technology, complemented by the creation and programming of an HMI interface for live operational oversight, ensuring real-time insights. We conduct thorough calibration and testing of safety features and alarms to guarantee reliability, followed by commissioning that aligns with international safety regulations, and conclude with a professional handover featuring comprehensive operator training and detailed documentation. Rely on MecTronic Services for a transformative safety upgrade delivered with superior expertise and adherence to global standards.

Watch project video

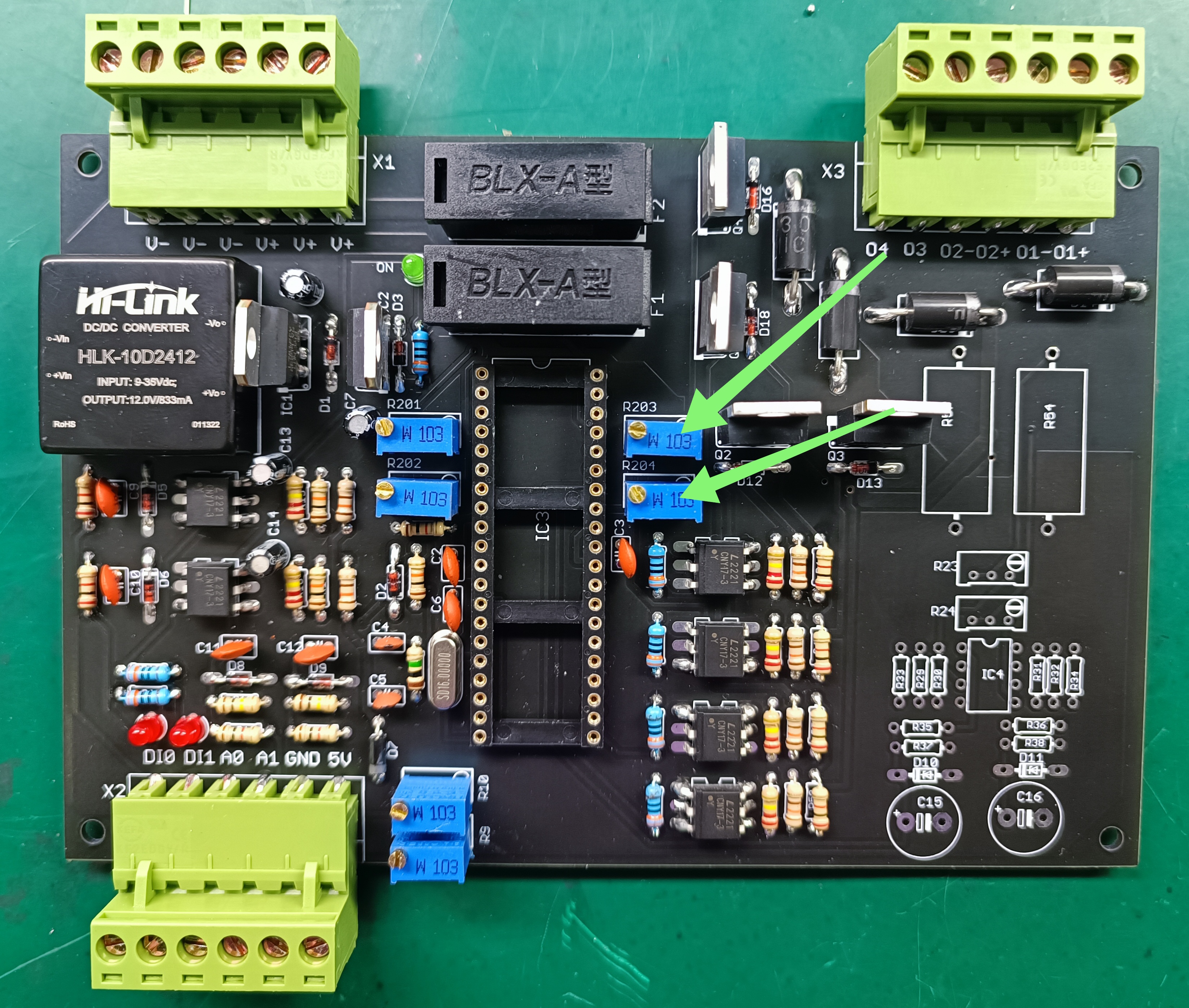

Control System Enhancement for Piling Machine

Transform your piling machine's efficiency with MecTronic Services' advanced control system enhancement, beginning with the custom design and assembly of a state-of-the-art electrical control panel to meet your operational demands, paired with the integration of a PLC system for superior automation and stability. Our experts incorporate a range of digital and analog input/output units with precision, complemented by expert wiring, cabling, and linkage of sensors and actuators for seamless functionality. We engineer intricate PLC programming and a user-friendly HMI interface to optimize performance, followed by extensive validation and activation of the enhanced system. The process wraps up with detailed technical documentation and a smooth handover, ensuring your team benefits from a reliable, high-performance solution. Count on MecTronic Services for an innovative upgrade executed with exceptional skill.

Watch project video

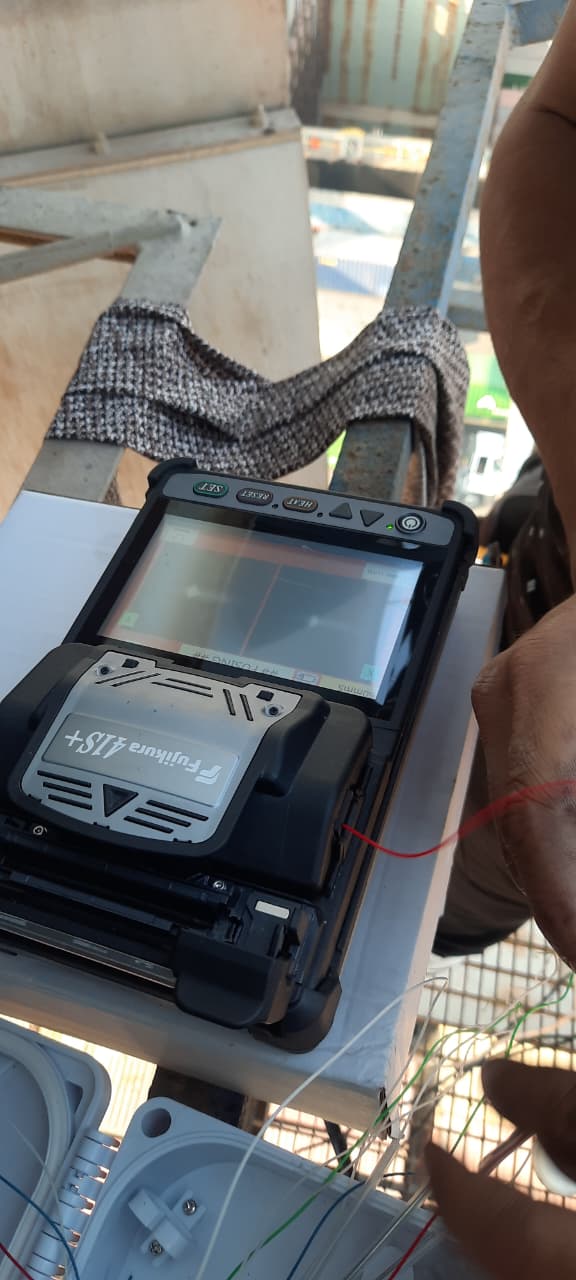

Fiber Optic Cable Splicing and Installation for Container Cranes

Enhance your container crane connectivity with MecTronic Services' expert fiber optic cable splicing and installation, starting with a detailed evaluation of crane structure and operational needs to ensure a perfect fit, followed by pinpointing the most effective cable routing paths. Our skilled technicians expertly pull and lay fiber optic cables across the cranes, securing and shielding them to endure movement and harsh environmental factors with resilience. We perform high-precision fusion splicing to guarantee seamless connections, complemented by the strategic placement of termination boxes and patch panels for robust infrastructure. Rigorous OTDR and power meter testing ensures superior signal quality and minimal loss, while comprehensive documentation and precise labeling of all fiber connections complete the process. Rely on MecTronic Services for a cutting-edge solution delivered with unmatched proficiency and care.

Watch project video

Design and Assembly of Electrical Panels for Damietta Port Authority Warehouses

Boost warehouse efficiency with MecTronic Services' expert design and assembly of electrical panels for the Damietta Port Authority, commencing with a thorough assessment of warehouse electrical requirements to align with operational goals, followed by precise calculation of total electrical load and equipment distribution. Our skilled engineers create detailed single-line diagrams (SLDs) to guide the process, selecting top-tier components such as MCBs, MCCBs, contactors, and relays to ensure reliability, while adhering to IEC standards and local regulations for compliance. We craft and wire main and sub-distribution panels with precision, integrating protection devices, meters, and terminal blocks for robust performance, and conduct insulation resistance, continuity, and functionality tests for quality assurance. After a comprehensive Factory Acceptance Test (FAT), we oversee the transport and installation of panels at warehouse sites, managing final connections and system energization under expert supervision. The project concludes with as-built drawings, technical manuals, and test reports, empowering your team with essential documentation. Trust MecTronic Services for a transformative electrical solution delivered with exceptional expertise.

Watch project video

Complete Overhaul of Engine, Hydraulic System, and Transmission for Hyster Crane

Optimize your crane's performance with MecTronic Services' meticulous overhaul of the engine, hydraulic system, and transmission for the Hyster Crane, beginning with a detailed assessment of all systems to pinpoint operational needs, followed by identifying worn-out or damaged components for targeted repair. Our experts conduct functional testing and performance evaluations to establish benchmarks, then proceed with dismantling and cleaning engine parts to ensure a pristine foundation, replacing critical components like pistons, filters, gaskets, and injectors with precision. We reassemble and fine-tune the engine to manufacturer specifications, while inspecting hydraulic pumps, valves, cylinders, and hoses, addressing faults through replacement or refurbishment and performing hydraulic fluid flushing and refilling for optimal flow. The process includes disassembling and cleaning gearbox and transmission parts, renewing worn gears, bearings, seals, and fluids, followed by testing shifting functions and alignment for seamless operation. All overhauled systems are reintegrated into the crane with careful alignment, calibration, and synchronization of mechanical and control systems, culminating in full operational testing under load conditions. Safety checks ensure compliance with OEM standards, validated by a comprehensive performance review and detailed delivery report, accompanied by maintenance and operation manuals, a final inspection report, and customer sign-off. Rely on MecTronic Services for a transformative overhaul delivered with outstanding expertise.

Watch project video

Excavator Bucket-Wheel Slewing Gear Replacement

MecTronic Services has successfully completed the replacement of the bucket-wheel excavator slewing gear bearing, showcasing our expertise in heavy machinery rehabilitation. This project, executed with precision, involved dismantling the old bearing and installing a new one, enhancing the excavator’s operational efficiency and longevity.

The scope included a meticulous two-phase process: preparation during crane operation and post-crane stoppage activities. This achievement highlights our capability to handle complex mechanical and electrical upgrades in challenging industrial environments.

Preparation Phase: Conducted soil bearing capacity checks and pit preparation (2m deep, 4m long, 3.5m wide with 45° sloped sides) to support lifting loads. Mobilized tools, removed grease, applied rust removal oil, and positioned the excavator over a prepared pit with metallic plates under counterweight and bucket wheel. Hot bolting and verification of soft spots, bolt lengths, and hydraulic pressures were performed, followed by mechanical and electrical isolation.

Replacement Phase: Involved electric crew disconnecting cables, lifting crew securing and lowering the column and slip ring base, and mechanical crew dismantling bolts and the old bearing. Welding crew provided support structures, while the new bearing was installed using hydraulic jacks, leveled, and bolted with torque application. Final steps included reconnecting lubrication and electric systems, removing temporary supports, and ensuring proper greasing.

This project demonstrated MecTronic Services' proficiency in coordinating multi-disciplinary teams, utilizing advanced tools like hydraulic jacks and torque wrenches, and adhering to safety standards, resulting in a fully operational excavator.

Watch project video

.jpeg)

.jpeg)

.jpeg)